Company news

Geographical Position

Orion Engineering Carbon (Qingdao) Co., Ltd., located in Fuzhou North Road, Jiaozhou City, Qingdao, is a wholly-owned subsidiary of ORION Group in China, a world-renowned carbon black manufacturer and the world's largest supplier in the field of specialty carbon black. Adopting German advanced equipment and process technology to produce carbon black, the products are in a leading position in the world.

01 New RO membrane reverse osmosis system project

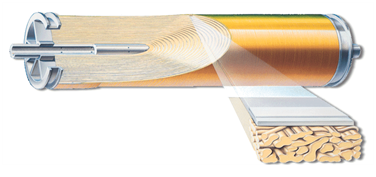

Orion Engineering Charcoal (Qingdao) Co., Ltd. originally adopted the traditional yin and yang bed treatment process. The local tap water has high salt content and alkalinity, the yin and yang resin consumes a large amount of acid and alkali, the amount of regeneration water is large, and the stability of the product water quality is slightly poor. In order to ensure the water requirements of the production process, the RO membrane treatment process is adopted and the concentrated water reuse unit is added to replace the traditional resin process.

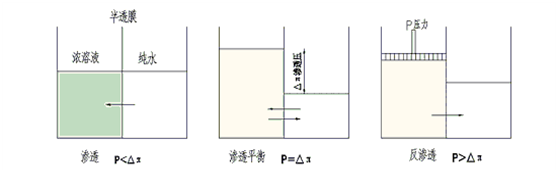

Reverse osmosis is also called reverse osmosis (RO), which uses a certain pressure to separate the solvent in the solution through a reverse osmosis membrane (or semi-permeable membrane). Because it is opposite to the direction of natural penetration, it is called reverse osmosis. According to the different osmotic pressures of various materials, the reverse osmosis method greater than the osmotic pressure can achieve the purpose of separation, extraction, purification and concentration.

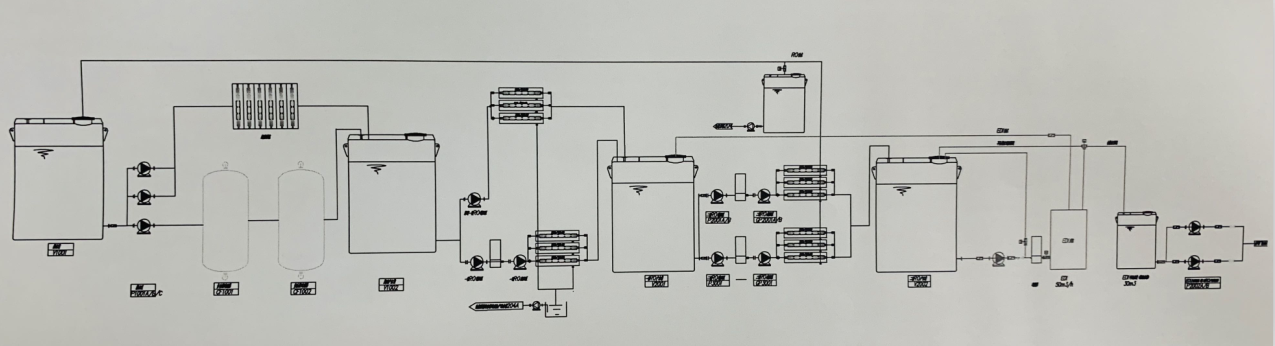

During the construction process of Winner Environmental Protection, the newly built RO membrane system and the concentrated water recovery RO membrane system are modularly designed. It occupies a small area and has a high degree of automation control. Manage complex situations. And the quality of the produced water is stable, the total water recovery rate is over 80%, and the daily operating cost is less than 50% of the original system.

Orion Engineering Charcoal (Qingdao) Co., Ltd.

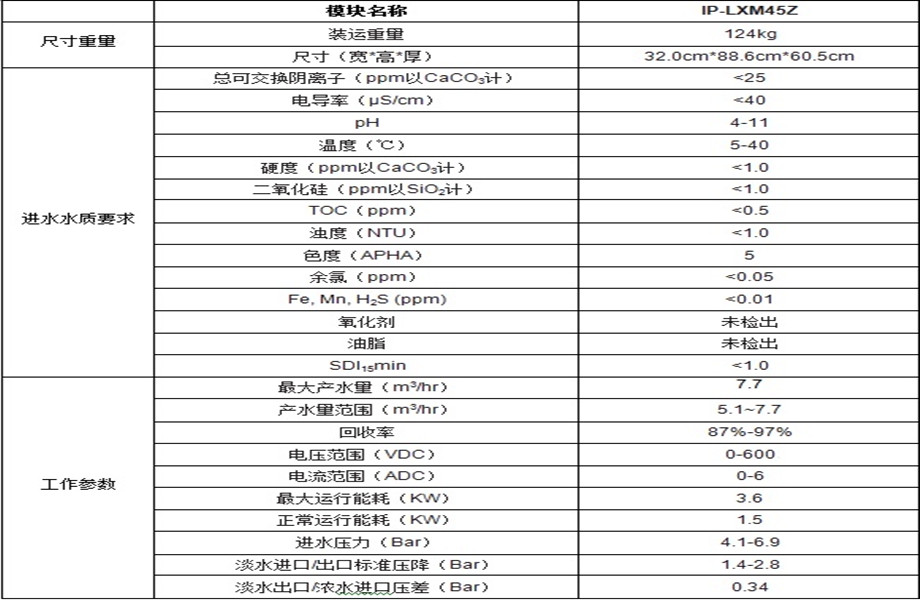

Technical requirements for the new RO membrane system project

The newly-built secondary RO membrane water production system has a water production capacity of 1000m3/d; the total recovery rate of the RO membrane system is ≥80%, and the salt rejection rate is ≥99.5%; the conductivity of the produced water is ≦5us/cm;

The project cycle is from April 10, 2020 to June 10, 2020. Winner Environmental Protection completed the supply, installation, commissioning and training of the new RO system, meeting the requirements of the contract and technical agreement, and delivered it to the owner for acceptance in September of the same year use.

02 Newly built EDI electric desalination system project

In November 2020, the 12MW steam turbine unit of Orion Engineering Carbon (Qingdao) Co., Ltd. launched the grid-connected power generation project using waste heat to produce exhaust gas. The waste heat power generation grid-connected power generation project does not increase any fuel consumption. It is completely green energy, equivalent to every year. Reduce coal consumption by 15,000 tons and reduce greenhouse gas emissions by nearly 40,000 tons. It has greatly improved the efficiency of power generation and energy recovery and the level of safe operation. It is estimated that 75 million kilowatt-hours of energy can be recovered every year. Winner Company has reconstructed and upgraded the supporting water facilities of Shandong Orion Waste Heat Recovery Machine Power Generation Project, and added an EDI electric desalination device to the 1000m3/d secondary RO membrane pure water system to replace the original mixed bed system and provide stability for the power plant And high-quality boiler make-up water promotes the company’s advanced concept of "clean production, green and environmental protection". The designed water production volume is 50m3/h, and the conductivity of the produced water is ≤0.2μS/cm. After the equipment is completed, the dosage of acid and alkali chemicals during the regeneration of the mixed bed is greatly saved, and there is no shutdown regeneration, continuous electric desalination, and reserved in the system automation The DCS system interface improves the management level.

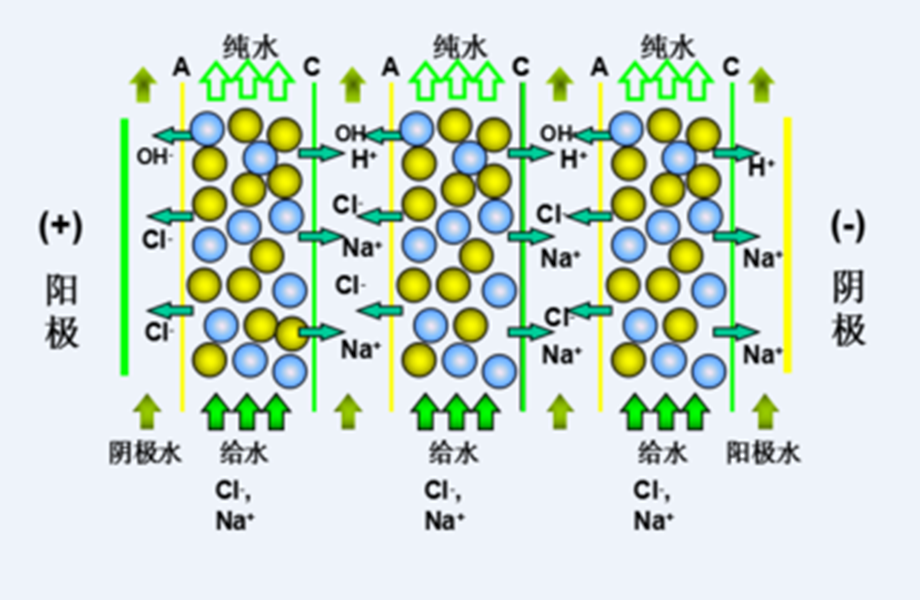

EDI water treatment flow chart ↓

EDI single group module parameters ↓

EDI (Electrodeionization, continuous electrolytic salt technology) is a pure water manufacturing technology that combines ion exchange technology, ion exchange membrane technology and ion electromigration technology. It cleverly combines electrodialysis and ion exchange technology, uses the high voltage of the electrodes at both ends to move the charged ions in the water, and cooperates with ion exchange resin and selective resin membrane to accelerate ion movement and removal, so as to achieve the purpose of water purification.

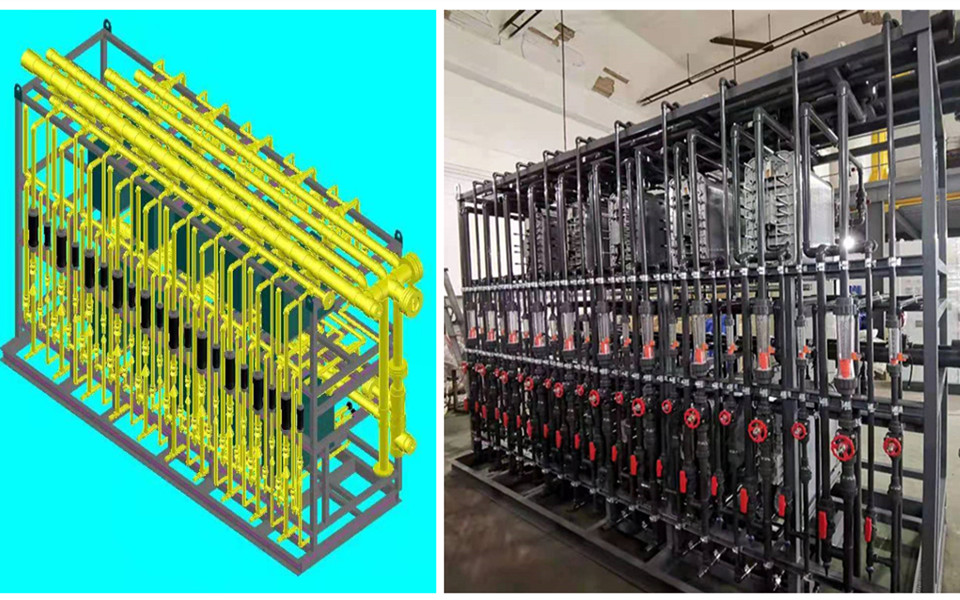

The EDI module is prefabricated in the workshop and put into operation quickly after the site is in place. The EDI integrated device includes 10 EDI membrane stacks, fixed supports and water inlet, fresh water, concentrated water, and CIP cleaning pipelines. The layout is compact and beautiful and easy to operate.

EDI three-dimensional design and equipment real-life map ↑

The project cycle is from February 18, 2021 to April 30, 2021. Winner Environmental has completed the supply of complete sets of EDI equipment, commissioning, and training for the Orion project, and will be delivered for acceptance in June this year.

"Innovation, cooperation, performance, and win-win"! Winner effectively combines global innovative water treatment technology with customers' green production needs to escort green factories.